Buck Converter Selection Guide

Buck Converter Definition

Buck converters are switch-mode step-down converters which can provide

high efficiency and high flexibility at higher VIN/VOUT ratios and higher

load current.

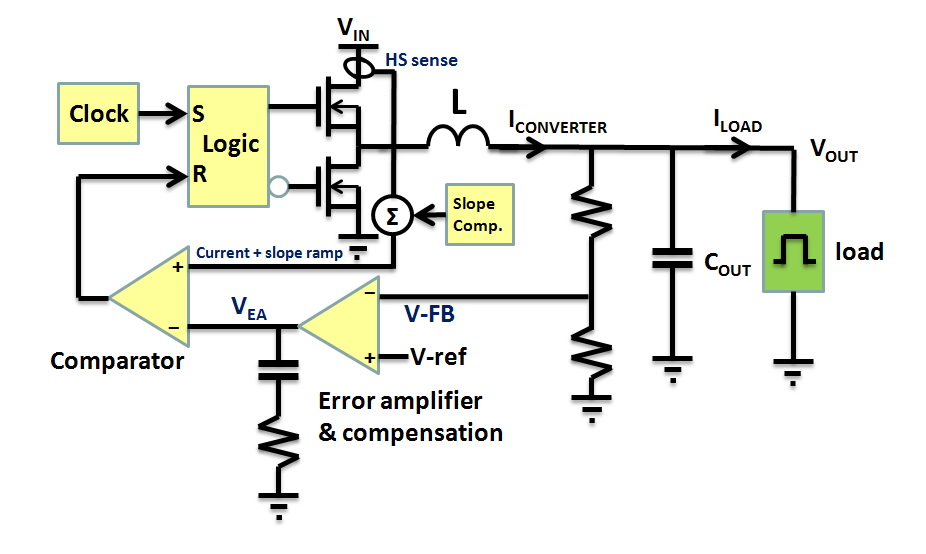

Most Buck converters contain an internal high side MOSFET and synchronous

rectifier MOSFET, which are in turn switched on and off via internal duty-cycle

control circuit to regulate the average output voltage. The switching waveform

is filtered via an external LC filter stage.

Buck converter features

Due to the fact that the MOSFETs are either ON or OFF, Buck converters dissipate

very little power, and the duty-cycle control makes large VIN/VOUT ratios possible.

The internal MOSFETs RDS(ON) mainly determines the current handling capabilities

of the Buck converter, and the MOSFET voltage ratings determine the maximum input

voltage. The switching frequency together with the external LC filter components

will determine the ripple voltage on the output. Higher switching frequency buck

converters can use smaller filter components, but switch losses will increase. Buck

converters with Pulse Skipping Mode (PSM) will reduce their switching frequency

at light load, thereby increasing light load efficiency, which can be important

in applications with low power standby modes.

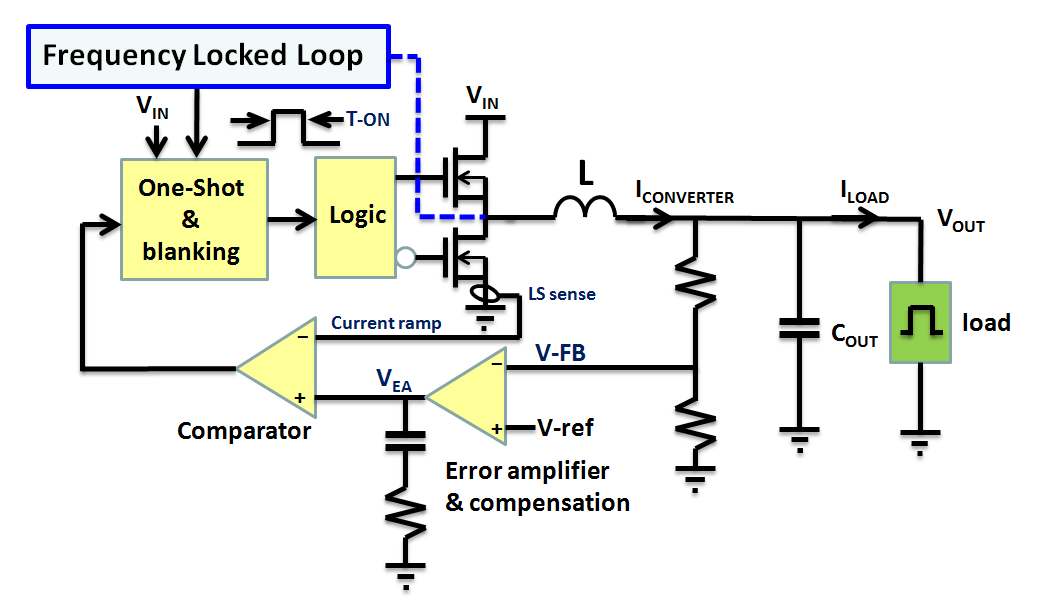

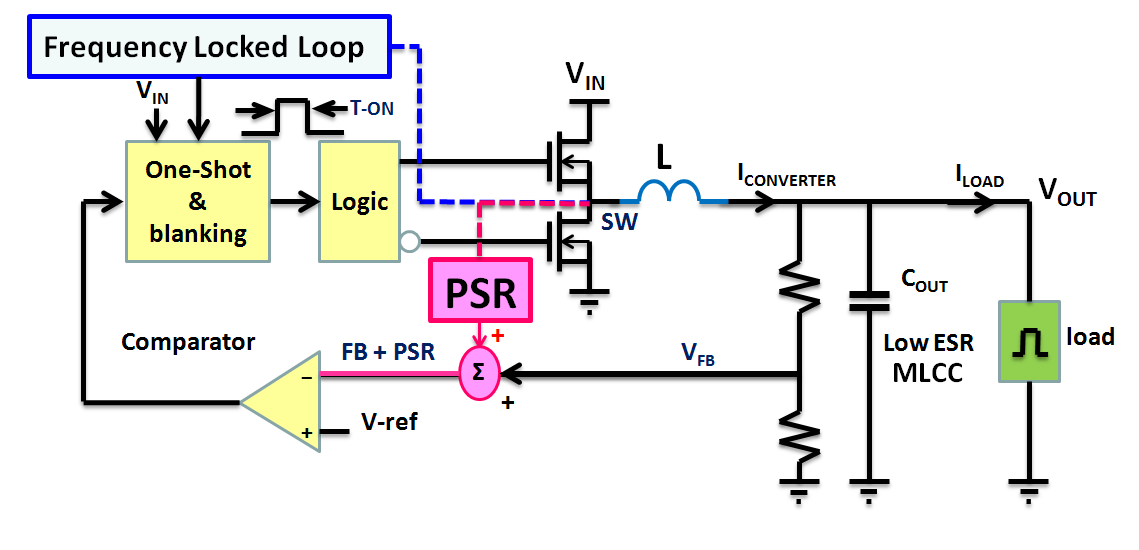

The Richtek DC/DC portfolio contains a wide range of Buck converters with different

control topologies, including Current Mode (CM), Current Mode-Constant On Time (CMCOT)

and Advanced Constant On Time (ACOT®) control topologies. Each topology is

suitable for different applications and requirements. For example, Richtek unique

ACOT® family has extremely fast transient response compared to CM and CMCOT

topologies, which makes it ideal for applications that exhibit very fast load transients,

such as DDR, Core SoC, FPGA and ASIC supplies.

Comparison table of Richtek buck

topologies

| Key features |

CM

Current Mode |

CMCOT

Current Mode

Constant-On-Time |

ACOT®

Advanced

Constant-On-Time |

| Topology |

|

|

|

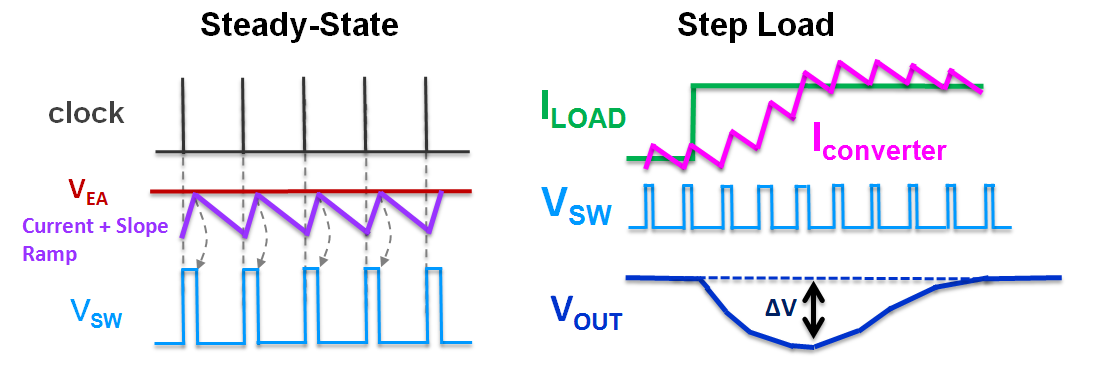

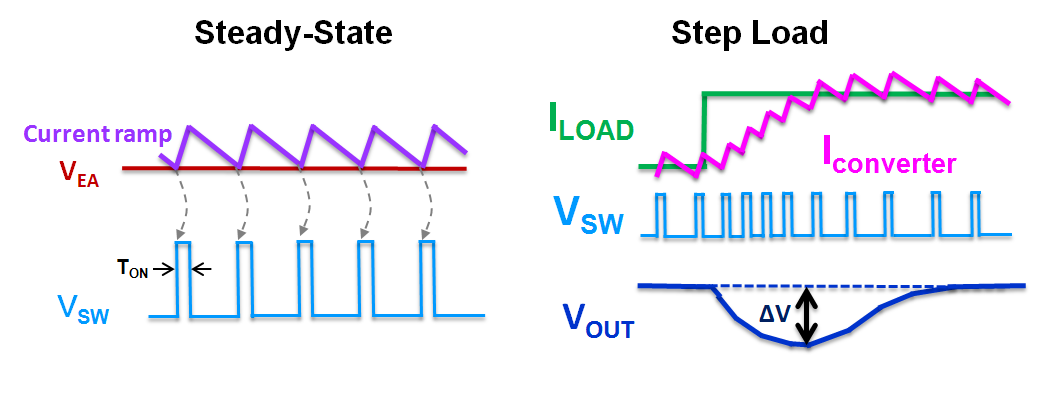

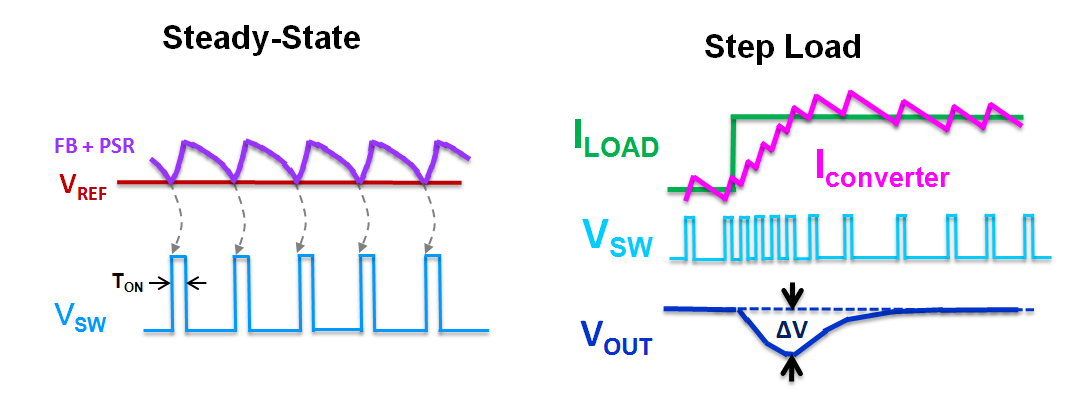

Steady-state &

Step load |

|

|

|

| VIN/IOUT range |

- 2.5Vin to 5.5Vin / up to 6A for low Vin and battery-powered applications

- Up to 36Vin / up to 10A

- Up to 60Vin for Industrial and 36Vin for Automotive applications

|

- 2.5Vin to 5.5Vin / up to 3A

|

|

Response to

Load Steps |

moderate |

fast |

extremely fast |

| Current Sense |

current sense limits min. ON time |

low side current sense |

Not required |

| Min. ON Time |

Larger, limits the min. achievable duty-cycle |

Small min. On time allows small duty-cycles |

Small min. On time allows small duty-cycles |

| Frequency |

stable fixed fSW |

constant average fSW |

constant average fSW |

| Stable with MLCC |

√ |

√ |

√ |

| Slope Compensation |

√ |

not required |

not required |

| Synchronized to ext. Clock |

√ |

X |

X |

| Richtek Designer™ simulation tool

|

Create your account and get your designs up and running in no time.

(partial parts have been released) |

Coming soon |

Create your account and get your designs up and running in no time.

(partial parts have been released) |

| Applications |

For applications with steady load conditions. Also for industrial and

automotive applications. |

For applications with moderate load transients, or applications that

require small minimum ON times

(i.e. high switching frequency in combination

with larger step-down ratios) |

For applications with severe fast load transients , such as DDR, Core

SoC, FPGA and ASIC supplies |

Buck Converter Selection Criteria

In order to select a suitable Buck converter for your application, some key criteria

are important to be considered.

Application input voltage

| Which upper bound

of input voltage fits for your application best? |

Richtek Buck converters can be divided into 3 main groups to fulfill

different application requirements. Richtek LV Buck converters are

suitable for running off single cell Li-Ion batteries as well as

supplies from 5V rails. The 18V rated HV Buck converters are often

used for applications that run from 12V. We also provide parts up

to 36V input range for industrial supplies or automotive applications

with large input voltage fluctuation.

|

Application current consumption

| How to calculate

the power loss and maximum application peak current? |

When considering the Buck converter current rating, there

are two factors to consider: The application average current consumption

and the application peak current.

- The application average current will determine

the average heat in switching MOSFETs which is related to conduction

losses and switching losses. Conduction losses are related to

the internal MOSFET RDS(ON) : The MOSFET conduction losses are

I2 * RDS(ON) ; Switching losses are mostly related

to the current, the input voltage and the switching frequency.

In most standard applications, the switching losses are roughly

30% of the total losses, but in applications with higher input

voltage or high frequency, the switching losses can increase

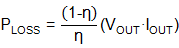

considerably. The application total power losses can be derived

from the datasheet efficiency curve:

.

.

- The device maximum rated current and over-current

protection level must be considered when checking application peak

load current. The difference between load current and inductor peak

or valley current is ½ the inductor ripple current, so be sure to

include this when checking the application maximum load current

in relation to OCP current levels.

|

Light load efficiency

|

When to select Force-PWM mode or PSM mode?

|

|

For supply rails that need to be active in low power standby modes, it is desirable to make the Buck converter efficiency at light load as high as possible. Force-PWM Buck converters keep the switching frequency fixed over the entire load range while Pulse Skip Mode (PSM) will reduce switching frequency at light load, thereby improving light load efficiency since the majority of losses at light load are caused by switching loss.

Read more for PSM operation principle and its advantages and drawbacks.

|

Switching frequency

Low BOM cost

|

How to reduce BOM cost?

|

|

Choosing the right Buck topology together with the most optimal IC package can bring you cost savings on both passive components and IC cost.

ACOT® topology offers superior load transient response, making it possible to reduce the size of your output capacitors and still meet the load transient voltage undershoot requirement.

Flip-Chip in TSOT-23-6 package offers lowest package cost, while maintaining good thermal performance and low RDS(ON) due to the absence of bonding wires. |

IC package consideration

|

Which IC package is most suitable for your application?

|

|

Richtek Buck converters are available in many types of packages: from tiny CSP 1.3x2.1mm to cost effective TSOT-23-6 to larger TSSOP-14 thermally enhanced package.

SOP-8 (exposed pad) and DFN2x2 and DFN3x3 packages are often used in Buck converters: Their pin count ranges from 6 ~ 12 pins for extra functionality, and they offer good thermal performance due to exposed thermal pad. They are cost effective, making them a popular choice for many applications. It is possible to use these parts in single sided layout, but for better thermal and electrical performance multi-layer PCB layouts are recommended. TSSOP-14 or WDFN-14L 4x3 have larger thermal pads, which allow them to dissipate more power. Read more to find design considerations for other packages.

|

Other considerations

|

|

|

External soft-start

All Richtek Buck converters have a soft-start function. After enabling the converter, the duty-cycle is gradually increased to allow a smooth rising output voltage, which avoids inrush current due to sudden charging of the output capacitors. Converters with internal soft-start have a fixed soft-start time. If the application uses very large output capacitance or requires a specific soft-start time, it is better to select a converter with externally programmable soft-start; the soft-start time can be set by an external capacitor.

External compensation

Current mode converters need error amplifier compensation to ensure stable operation. The type-II compensation components determine the converter bandwidth and the phase boost frequency. Converters with external compensation have more flexibility in setting the desired bandwidth and phase margin with different types of output capacitors over a wider range of input and output voltage conditions.

Programmable frequency

Some converters have a programmable frequency function: The switching frequency can be set by means of an external resistor.

This gives more flexibility in choosing the best switching frequency for the application; higher frequency to reduce ripple or component size or get better transient behavior, or lower frequency to improve efficiency or reduce higher harmonics.

External sync input

Some current mode converters have an external sync input that allows the internal clock to be synchronized to an external clock signal. This makes it possible to set the switching frequency at a very precise value (for avoiding noise at sensitive frequency bands), and also make it possible to run several converters at the same frequency.

Low-Dropout mode or 100% duty-cycle mode

Many current mode Buck converters from the LV series have Low Dropout mode function: When the input voltage drops, these Buck converters gradually increase the duty-cycle and will continuously switch-on the high side MOSFET when the input voltage drops below the regulated output voltage. This function is especially suitable in battery powered applications, and can extend application operation time when the battery is almost depleted.

Power Good function

The Power Good function will monitor the Buck converter output signal and provide a means of telling the system when the output voltage is within a certain operating range. Power Good can be used for system initialization, fault detection or start-up sequence.

Over Current Protection

All Richtek Buck converters have Over Current Protection (OCP). When the inductor current exceeds the OCP level, the converter duty-cycle is limited. Further load increase will result in output voltage drop. However, there are different ways how the system behaves in overload condition:

- Latch mode OCP: When during overload the output voltage drops below the Under Voltage Protection (UVP) point, the system shuts down and latches. The converter needs to be re-enabled or cycle the input voltage for restart. This protection ensures zero power after overload, but does not have auto restart.

- Hiccup mode OCP: When during overload the output voltage drops below the UVP point, the system shuts down and initiates a restart with soft-start. Continuous overload will show continuous shut-down/restart cycle or hiccup mode. The advantage of hiccup mode is low average overload current, and guarantees auto restart after the overload is removed.

- Non UVP: During overload the output voltage drops, but there is no UVP action. The system continues to run at OCP current level during overload. The output voltage recovers immediately after the overload is removed. But the continuous OCP current level can lead to increased temperature in longer term overload conditions.

|

Richtek Buck Product Family

-

-

-

The proprietary ACOT control scheme not only features ultra-fast

transient response but also improves upon legacy constant on-time

architectures, achieving constant average frequency over

line, load and output ranges to minimize interference and noise problems.

The ACOT Buck converters are stable with and optimized for ceramic

output capacitors without external components or external ripple

injection scheme. The ACOT family includes latch-off, hiccup and

constant current protection modes. Richtek has introduced the whole

range of ACOT Buck converters up to 12A output current

capacity and the input range is from 4.5V to 23V. The ACOT

Buck converters are ideal for Set Top Boxes, industrial

and commercial low power systems, computer peripherals

and LCD Monitors and TVs. See the list of

ACOT products.

-

Richtek offers comprehensive power conversion solutions for input voltages

ranging up to 60V, suitable for a wide range of applications in the industrial,

automotive, and professional lighting field. The key features for Buck converter

parts in wide input range are: Robust control architectures for coping with

noisy environments, PGOOD and adjustable Soft-start for power sequencing,

thermally enhanced packages for operation in higher ambient temperatures,

and fully stable with all ceramic input and output capacitors for extended

operation life time. We also offer products qualified over -40°C to

85°C industrial temperature range as well as automotive AEC-Q100 standard

qualified parts.

See the list of selected products.